The main source of heat generation in transformer is its Copper Loss Or l'r Loss. Although there are other factors contribute heat in transformer such as hysteresis & eddy current losses but contribution of l'R loss dominate them. If this heat is not dissipated properly, the temperature of the transformer will rise continually which may cause damages in paper insulation and liquid insulation medium of transformer to avoid this Thermo Engineers Pvt Ltd offers following range of cooling solutions based on the customer requirements.

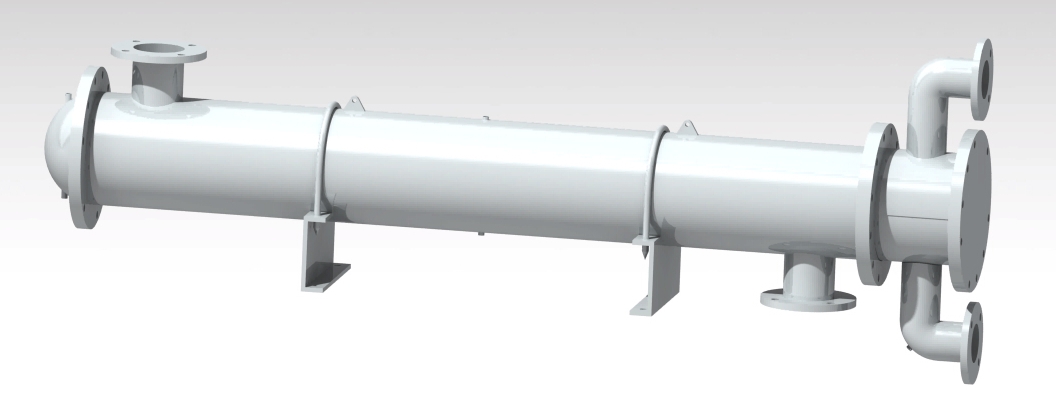

The transformer oil is heated by the heat losses of the windings. This oil is cooled by water in shell & tube type oil coolers.

| Power Rating | 50-2000 kW/Each |

| Cooler Orientation | Vertical and Horizontal mounted |

| Cooler Construction | Fixed tube plate, Floating tube plate, |

| Tube Execution | Single and Double For both the above executions (Single and double tubes) and depending on the cooling water following materials are used |

| Tubes | Copper, Copper-Nickel (70:30), Copper-Nickel (90:10), Admiralty Brass, Stainless steel 304/316, Titanium |

| Tube Plates: | C-Steel, Naval brass, Stainless steel 304/316, Copper Nickel (70:30),Copper-Nickel(90:10), Titanium. |

Our Double wall type coolers are designed and manufactured with special care where transformer oil cooling is a critical application. Because we understand that failure in transformer due to cooler leakage may lead to heavy financial losses.

Unlike single tube coolers, this execution of the tube bundle requires double tubes. This special safety design prevents the chances of water and oil mixing in heat exchanger and also the cooling water pressure is not limited by oil pressure. Also the processes need not to be terminated immediately after the failure. Thus keeping the transformer in service. In case of leakage, water or oil is led into the chamber between tubes and the tube plates, therefore the double tube system always prevents water and oil from mixing.The double tube design is the most valid solution to protect the transformer, especially when, using sea or industrial water, and where the site maintenance is not easy. In case of leakage an alarm is provided to a leakage detector provided at the collecting box fitted to the cooler.

| Power Rating | 50-2000 kW/Each. |

| Cooler Mounting | Vertical andHorizontal mounted. |

| Cooler Construction | Fixed tube plate, Floating tube plate. |

| Tube Execution | Double tubes (Inner & Outer tubes).Depending on the cooling water specifications tube materials are used. |

| Tubes | Copper, Copper-Nickel (70:30), Copper-Nickel (90:10), Admiralty Brass, Stainless steel 304/316, Titanium. |

| Tube Plates | C-Steel, Naval brass, Stainless steel 304/316, Copper Nickel (70:30), Copper-Nickel (90:10), Titanium. |

| Power Rating | 25-800 kW/each |

| Cooler Mounting | Tank mounted, Separate Assembly |

| Cooler Construction | Fixed tube plate, Floating tube plate. |

| Cooler Arrangement | Vertical / Horizontal |

| Tubes | Copper Cu:ni-90:10 C-Steel Stainless Steel |

| Fins | Copper ,Aluminum |

| Tubes Plates | Aluminum C-Steel Stainless steel |

OFAF TRANSFORMER OIL COOLER/ COMPACT COOLER