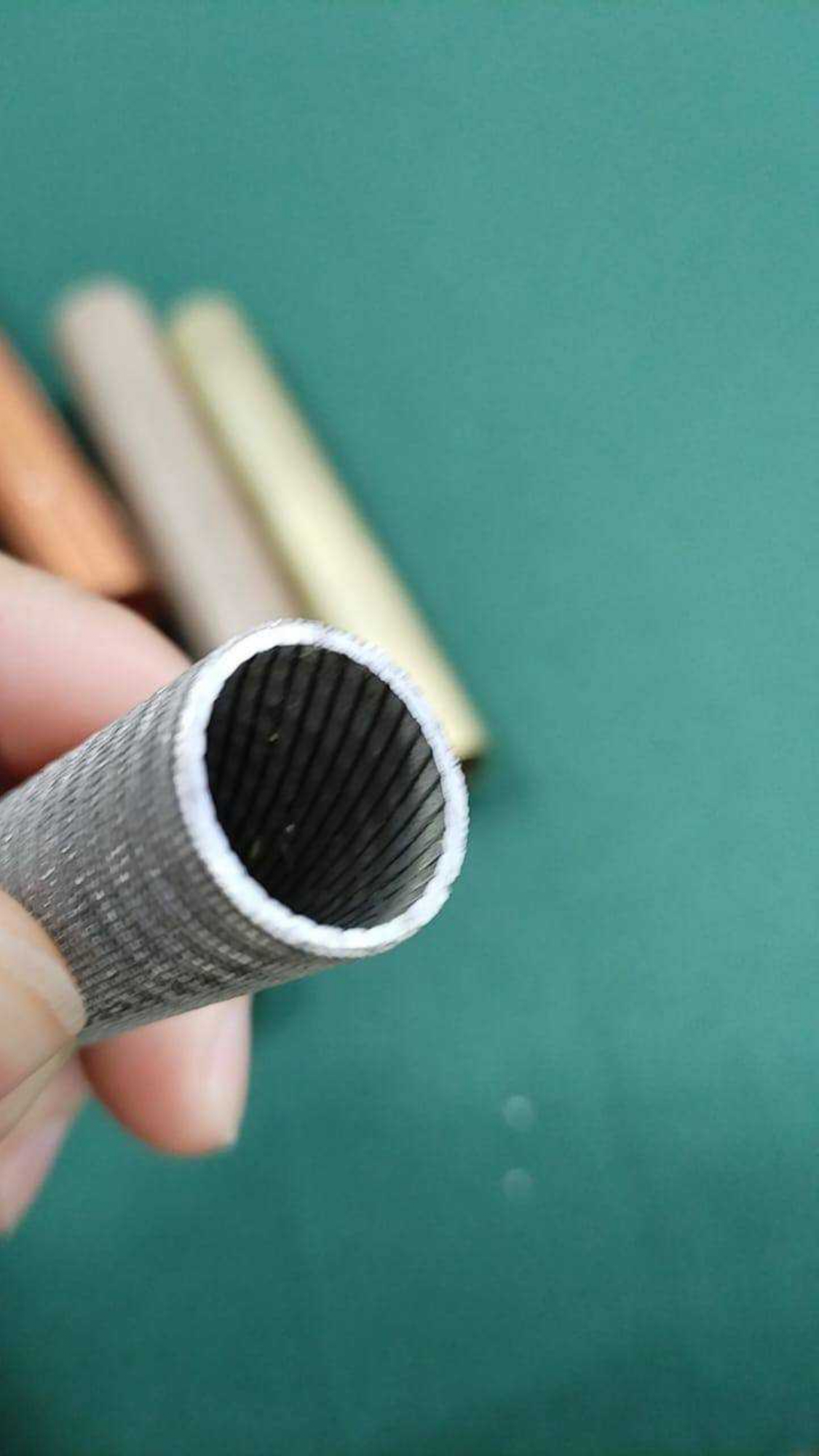

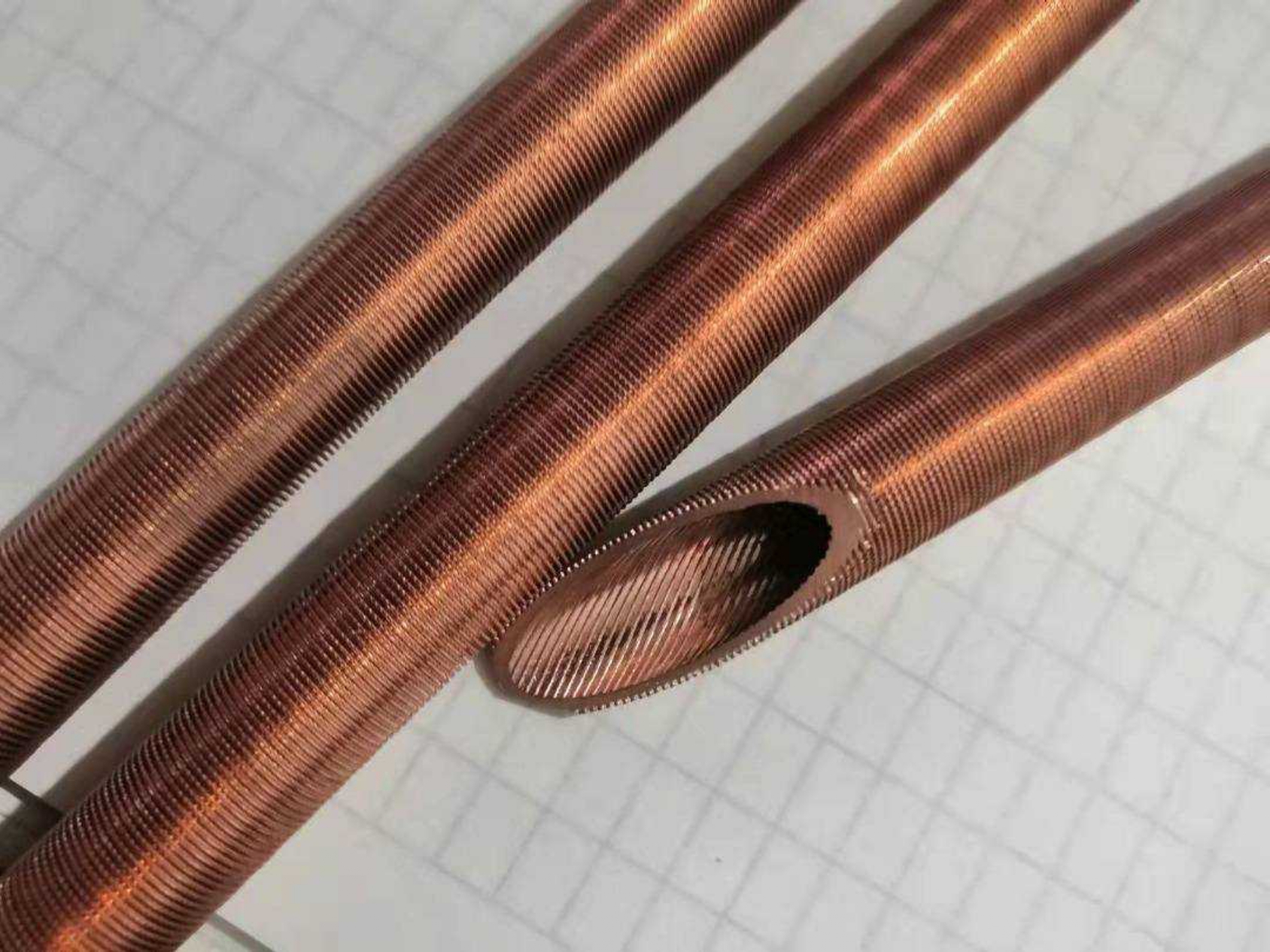

Our integral finned tubes are designed for enhanced heat transfer efficiency, durability, and performance. Manufactured using advanced cold rolling and extrusion techniques, these tubes offer superior thermal conductivity, corrosion resistance, and mechanical strength for a wide range of industrial applications.